Pioneering microscope analysis technique offers “enormous potential” to develop new breed of highly efficient tyres Sumitomo Rubber Industries & Ibaraki University establish technique to selectively observe individual materials within tyre rubber to help develop new generation of tyres

Sumitomo Rubber Industries (SRI). with Ibaraki University, have established a new technique to observe and analyse individual materials within tyre rubber. Engineers claim this pioneering research offers ‘enormous potential’ to use the information to develop high performance tyres with unprecedented levels of efficiency and wear resistance.

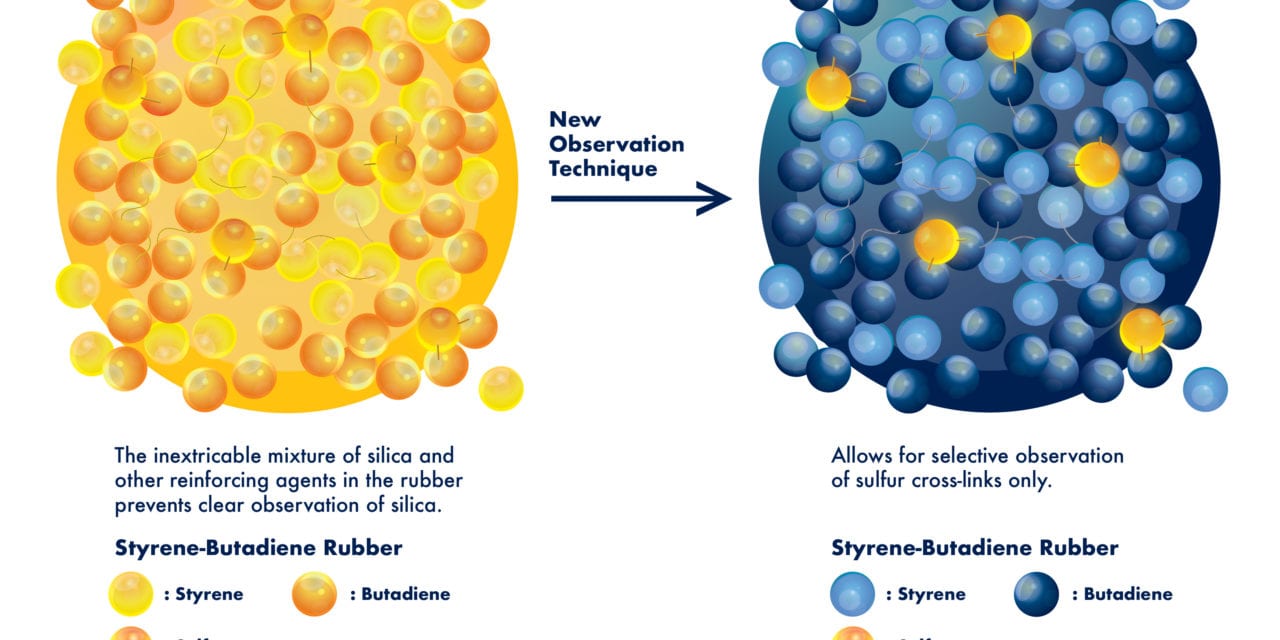

The rubber used in automotive tyres is made up of dozens of different types of materials including polymers such as natural and synthetic rubber, reinforcing agents containing carbon and silica and so forth. These various materials form complex, hierarchical structures within the rubber that directly affect performance. For example, the structures formed by sulphur cross-links, which give rubber its elasticity, have long been thought to be closely related to rubber strength and changes in rubber properties over time (such as degradation). Until now, the details of these structures within rubber have been a mystery.

To understand these interactions, a new particle beam microscope was developed by Ibaraki University in Japan. It can evaluate the actual rubber used in mass-produced tyres rather than less representative processed test samples. The microscope generates clear images of elements such as the sulphur cross-links or reinforcing agents and assigns specific colours to each element to clearly identity them.

“Being able to evaluate the very structures of tyres themselves, provides us with image data which can be used to develop internal structures for future tyres that provide superior performance in terms of fuel efficiency, wear resistance and so forth,” says Sumitomo Rubber Europe GmbH’s Dr Bernd Löwenhaupt. “This breakthrough offers enormous potential for the acceleration of our material development process. Using this technique, we have already succeeded in observing both coarse areas and fine areas (i.e. density) of sulphur cross-links (*1) within rubber in vivid detail for the first time (*2).

Notes

*1: Mixed into uncured rubber, sulphur serves to link polymer molecules together under the heat and pressure of the curing process, which gives the cured rubber greater elasticity.

*2: Refers specifically to the selective observation of sulphur cross-link density at the nanometre scale (based on in-house research).

ENDS

Falken Tyre Europe Falken Tyre Europe GmbH is the European affiliate of Japanese tyre manufacturer Sumitomo Rubber Industries Ltd. (SRI); with more than 37,852 employees, it is the fifth largest tyre manufacturer worldwide. In 2001 and 2014 SRI was selected to appear in the Thomson Reuters ‘Top 100 Global Innovators’ list of the world’s most pioneering companies. From its location in Offenbach, Main, the company markets and sells a complete tyre portfolio for passenger cars, light trucks, trucks, pick-ups and SUVs as original equipment and for the entire European retrofitting market. All Falken factories comply with the ISO 9001, IATF 16949 as well as environmental standard ISO14001. Developed and tested in the world’s most demanding racing series, Falken tyres provide maximum driving pleasure. The Falken brand is involved in exciting and high technology platforms such as motorsport with two Porsche 911 GT3 R race cars, at the BORUSSIA PARK stadium, which is the stadium of Bundesliga club Borussia Mönchengladbach, and as the global tyre partner of Liverpool FC.

[http://tracking.vuelio.co.uk/tracking/open?msgid=4xSaql7N7J18e48PpoCx1g2&c=1004757754335916985]